Mounting version of electric motors

Mounting version of electric motors

Electric motors are widely used in both commercial and industrial applications, ranging from small household appliances to large machinery. The design of electric motor mounts plays a crucial role in their selection and application. In this article, we will look at different types of motor mounts (mounting designs) and the factors that influence their choice.

There are three main mounting designs for electric motors: foot, end and flange, and two combined designs: foot with flange and end (small flange). Each design has its own advantages and is used for specific needs and mechanisms. Let's take a closer look at each of them.

Foot motors

Mounting version IM 1081 (designation according to GOST - B3)

Foot motors have a base that supports the motor. Foot mounts come in a variety of shapes, sizes, and materials, including steel, aluminum, and cast iron. These motors are typically used in the engineering industry where they require an intermediate transmission system, such as belts or gears.

The foot motor base ensures stable operation and the motors can be mounted either vertically or horizontally. The foot-mounted design provides a high degree of flexibility for the engineer's choice of location and is suitable for applications where the motor does not need to be moved frequently.

Motors with end mounting

Mounting version IM 3181 (GOST designation B14)

End-mounted motors (commonly called "small flange") are motors that are bolted directly to the equipment to be driven. These motors are typically used in small devices such as pumps and fans. End mounts are ideal when there is not enough space for other types of motor mounts.

End mounts provide easy installation, no brackets or base plates, and low noise and vibration due to direct drive. However, they have less positioning flexibility than other types of mounts.

Flange motors

Mounting version IM 3081 (GOST designation B5)

Flanged motors are mounted with bolts through the stator end of the motor. These motors are often used in vertical and horizontal mechanisms where space and other design constraints make other forms of mounting difficult.

Flange mounts provide easy installation and high precision due to the direct connection. They offer more positioning flexibility than end mounts, but not as much as foot mounts. Flanged motors are suitable for mechanisms requiring larger motors and more power.

Combined electric motors

Foot + flange (IM 2081, according to GOST - B35); Foot + end ("small flange") (IM 2181, according to GOST - B34)

Combined motors include those that, in addition to flange or end mounting, have additional mounting on the legs. Their undoubted advantage is an ultra-tight fit to the mechanism and very precise positioning during installation, which makes it impossible for the motor to move during operation due to the vibration of the mechanism.

The main disadvantages are that the electric motor requires a specially created place in the drive and additional supports for attaching the legs.

Factors influencing the choice of mounting design.

Several factors must be considered when selecting a motor with a specific mounting design and mounting structure, including load requirements, operating environment, available space, and vibration levels. The mounting design must also ensure proper alignment between the motor and the drive equipment.

Load requirements include motor power and stator magnetic field speed. These factors determine the size and shape of the motor and, therefore, the type of mounting required.

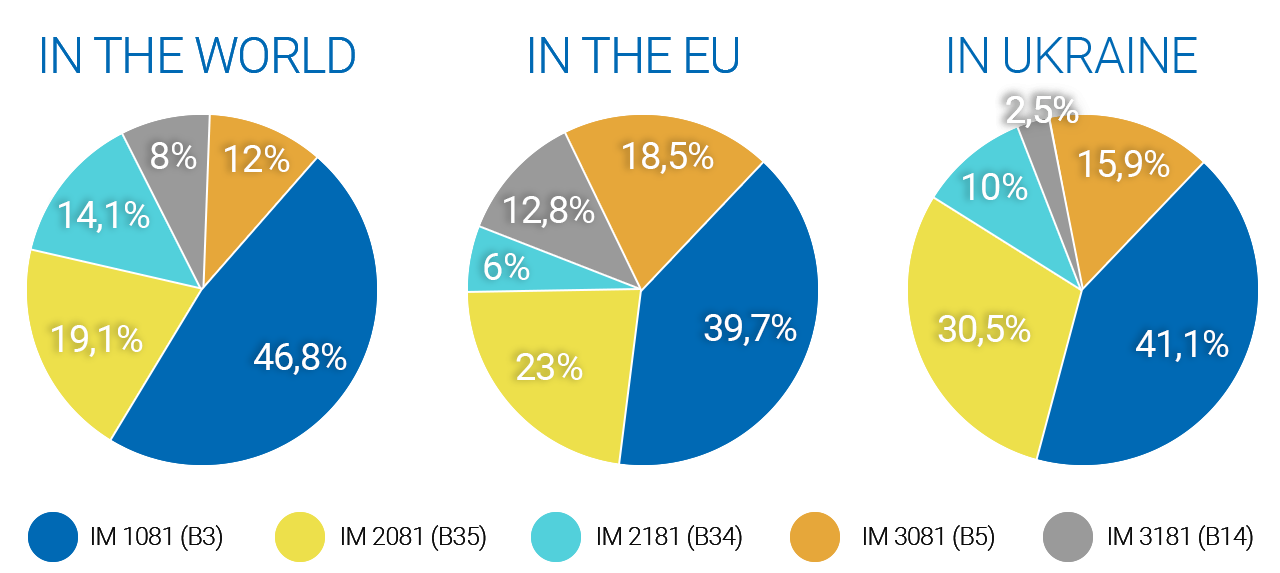

Interesting statistics. The ratio of the use of motors with different types of mounting in the industry (in the world, in the European Union, in Ukraine)

*Data as of January 2023. Statistical data from ABB, Siemens, Evropstat.

In our catalog you can choose three-phase and single-phase electric motors with any type of mounting.